Sustainable manufacturing more relevant than ever

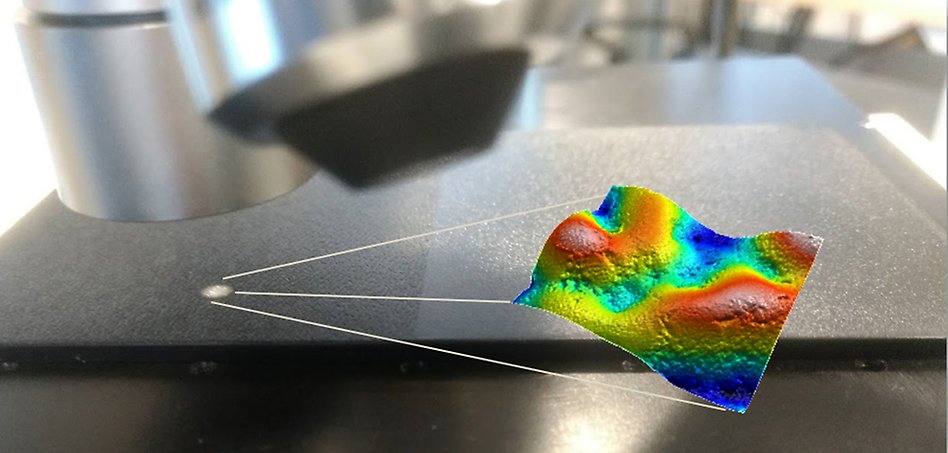

With the rise in demand for manufactured products, combined with depleting resources, sustainable manufacturing is now more relevant than ever. New research from Halmstad University and Chalmers University of Technology uses surface topography investigations in order to identify optimal process parameters, optimise process efficiency and drive sustainable manufacturing.

”Overall, the research process has been fascinating. Surface investigations help in exploring and understanding the behaviour of novel materials and current manufacturing techniques, which can be used for producing customer-specific products and boosting re-manufacturing and recycling.”

Vijeth Venkataram Reddy

Vijeth Venkataram Reddy

Vijeth Venkataram Reddy is a PhD student at Chalmers University of Technology but is employed at Halmstad University. His research focuses on developing methods for identifying what features, in relation to ISO surface parameters, are of interest when it comes to engineered surfaces.

”Every manufacturing process generates surfaces which behold certain signature features. Engineered surfaces consist of both features that are of interest and features that are irrelevant. I am using statistical methods for identifying the relevant deterministic features represented by ISO surface parameters”, he explains, and continues:

”By characterisation and analysis of relevant features the understanding of the manufacturing process and its influence on surface functional properties such as wettability, fluid retention, friction, wear and aesthetic properties can be improved. What impact these features have on the manufactured part vary depending on the process, materials, tooling and manufacturing process variables.”

What are standards?

Standards are jointly agreed solutions to recurrent problems. They are found in every area: from the simplest nail and screw to data communications, healthcare and the environment. The application of standards is voluntary, but may function as an obligatory reference, as in the regulatory and procurement processes adopted by public authorities. A standard may contain product-performance requirements, describe how they may be tested or define the content of services and how they should be performed. It may also contain joint terminology or describe common symbols and signs.

International Organization for Standardization (ISO)

Standards for, among other things, surface roughness are decided by the International Organization for Standardization (ISO). The organisation brings together experts to share knowledge and develop voluntary, consensus-based, market-relevant international standards that support innovation and provide solutions to global challenges.

Swedish Institute for Standards (SIS)

The Swedish Institute for Standards (SIS) participates in the global networks that create standards, e.g. ISO. It is an international organisation specialised in national and international standards. SIS acts as project manager for Swedish and international efforts to develop standards and promote their use. They also offer training, services and products that help customers develop their businesses and create societal benefits with the help of standards.

No perfect surfaces

Vijeth Venkataram Reddy does not propose a one-stop solution to all surface topography problems. However, he believes that it is possible to achieve surface topographies that are ideal for certain surface functions.

”The research methods that I have used can be applied to different manufacturing processes as a way to support the development of guidelines for the manufacturing industry’s focus on process optimisation through surface analysis”, he says.

To understand the mechanics of materials with respect to the manufacturing process it is important to investigate and unravel the underlying physical phenomenon of the produced surface topography.

”Overall, the research process has been fascinating. Surface investigations help in exploring and understanding the behaviour of novel materials and current manufacturing techniques, which can be used for producing customer-specific products and boosting re-manufacturing and recycling. Also, my research is well aligned with the sustainable development goals proposed by the UN. The goals focus on ensuring resource efficiency, reduce waste and mainstream sustainability practices”, says Vijeth Venkataram Reddy.

About the thesis

Title: On Deterministic Feature-based Surface Analysis External link.

The thesis was presented at Chalmers University of Technology May 27, 2020.

Read more

Read the article in Swedish: Hållbar tillverkning mer relevant än någonsin External link.