Increased opportunities in 3D printing through surface analysis

Amogh Vedantha Krishna, recent PhD in Manufacturing Technology does research on additive manufacturing, often known as 3D printing. Photo: Ida Fridvall

Hi there, Amogh Vedantha Krishna, recent PhD in Manufacturing Technology. You completed your PhD in December. Can you tell us a bit about your research?

“In short, it’s about additive manufacturing (AM), often known as 3D printing. The technique has developed a lot over the past years and is a well-used alternative when producing plastic and metal parts for a range of different products. However, there is still a great need for improving surface quality in order for 3D printing to replace conventional manufacturing techniques. With that said, my PhD thesis presents diverse research findings for surface improvement in additive manufacturing. The findings from this research can be utilised as a guideline for AM users who are looking to optimise the process through surface analysis.”

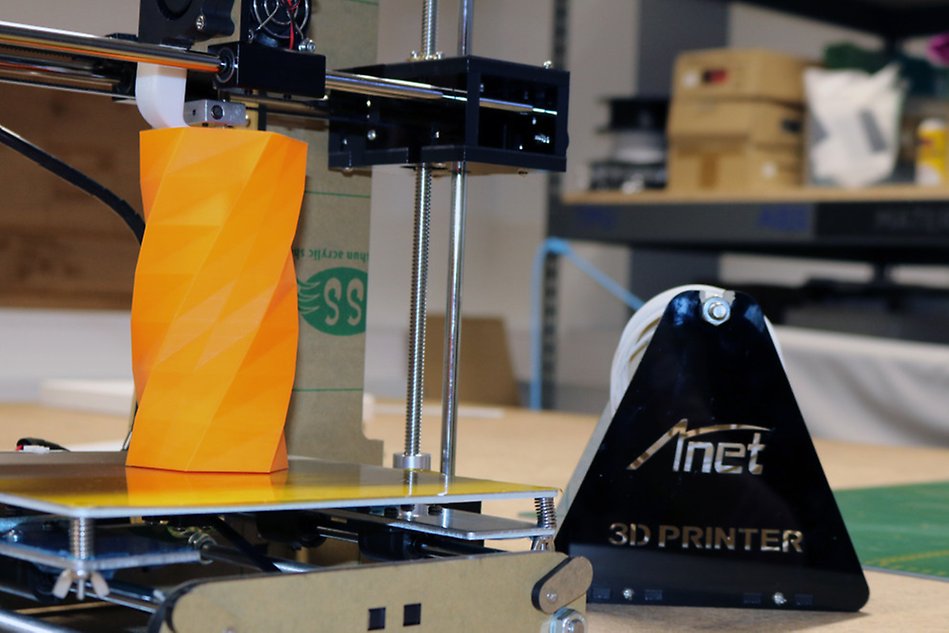

The 3D The technique has developed a lot over the past years and is a well-used alternative when producing plastic and metal parts for a range of different products. Photo: Christa Amnell

How can society benefit from your research?

“AM has several sustainability advantages – customisation, reduced energy consumption, less wastages, reduced tooling, inventory storage, low carbon footprints, faster time to market, and so on. The technology can also be utilised in the medical and dental sectors and for consumer goods, making it very beneficial not only for society, but for the environment as well.”

You were admitted as a PhD student at Chalmers University at the same time that you were employed at Halmstad University and carried out your research studies here. Can you tell us more about that?

“I started the Master's Programme in Mechanical Engineering at Halmstad University, a suitable programme based on my experience from industry and studies in mechanical engineering. While writing my master's thesis, I was offered a position as a research assistant. I worked for two years doing various projects before I got a PhD student position at Chalmers University. So I am a Chalmers PhD student, but most of my work is at Halmstad University under the supervision of Professor Bengt-Göran Rosén.”

”Additive manufacturing has several sustainability advantages – customisation, reduced energy consumption, less wastages, reduced tooling, inventory storage, low carbon footprints, faster time to market, and so on.”

Amogh Vedantha Krishna, Doctor of Philosophy in Manufacturing Technology

What are your plans for the future?

“I absolutely love the technology of additive manufacturing that I have majored in, and also the field of materials science. I am looking for opportunities to work in this area, not only to enhance my knowledge but also to contribute to society by providing more research publications, education, improving the technology and helping industries in using AM in their production.”

Text: Ida Hammar

About the PhD Defence

The PhD defence took place on December 15, 2022, at Chalmers University.

The dissertation’s title: “On Characterization and Optimization of Surface Topography in Additive Manufacturing Processes" External link..

- Opponents: Mohamed El Mansori, Professor, Ecole Nationale Supérieure d'Arts et Métiers, ParisTech, France

- Supervisors: Bengt-Göran Rosén, Professor, Halmstad University